Web page for LHC Interconnect Coordination & Support

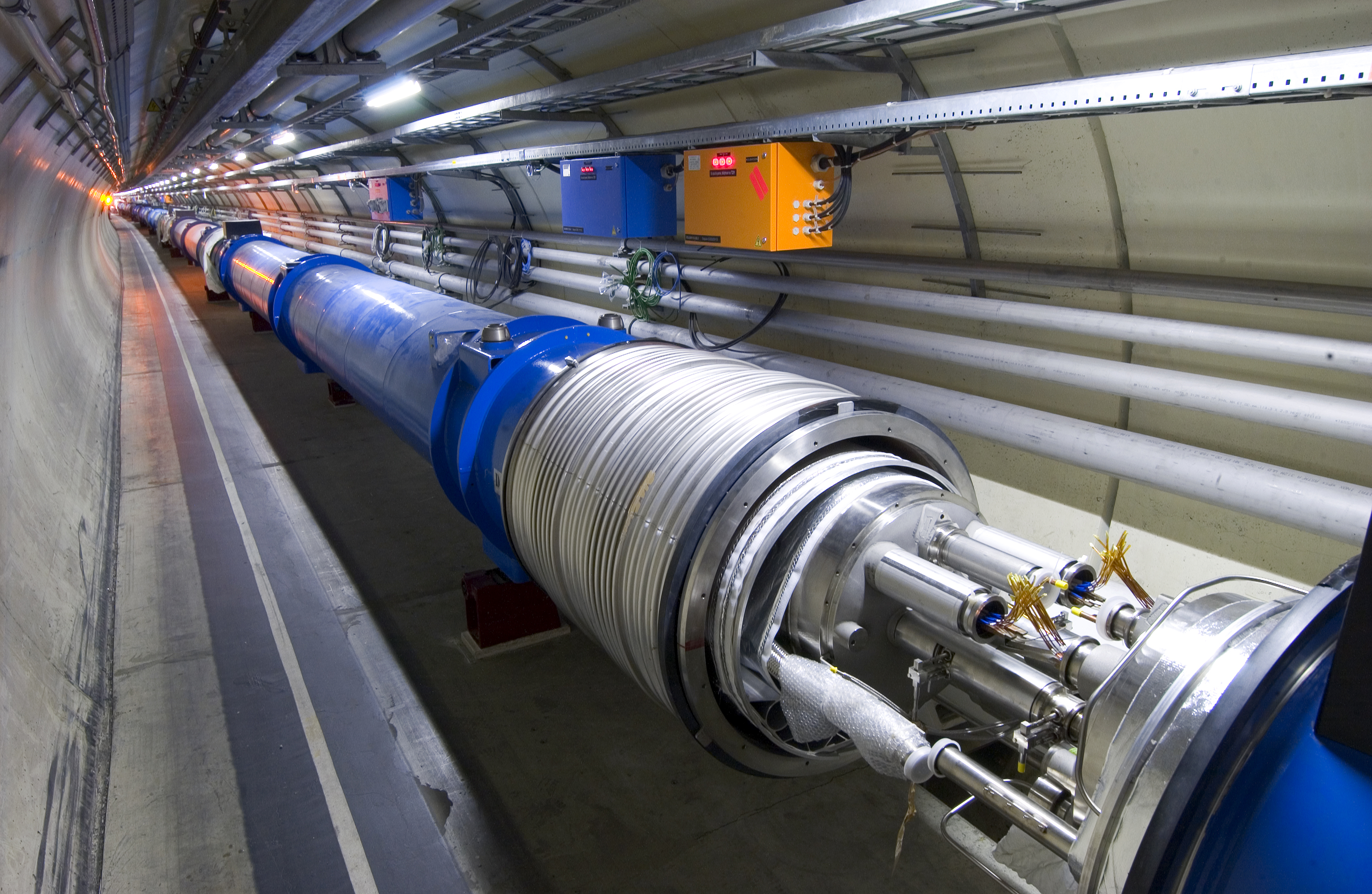

Picture shows the LHC tunnel

with a Dipole/Dipole

interconnection still open.

Interconnections telephone list

Contents of this page:

Status by sector:

Sector 1-2

Sector 2-3

Sector 3-4

Sector 4-5

Sector 5-6

Sector 8-1

Other web pages:

Reference

documents and

drawings:

LHC Interconnections

naming

and position

convention

LHC

Interconnections

drawings

(CDD account needed)

Interconnection Leader:

F. Bertinelli

(AT-MCS)

Arc coordination team:

P. Fessia

(team leader): general planning, IC organization

P. Legrand:

infrastructure, coordination of PEFRAs

A. Musso:

sector coordination

A. Sajous, logistic

and stock responsible

M. Struik:

arc interconnection component manager

C. Vollinger:

detailed planning,

coordination of DS regions.

Mandate -

Status - Work Flow Chart

-

Presentations/Reports

≥ Mandate

Coordination and support of the interconnect works in the LHC tunnel.

The arc extends between DFBA-to-Q7 interconnects (except some activities in the DS area associated to DFBA IC work).

The responsibility begins with the start of the IC work and ends with the closure of the W- and Z-bellows and the leak tightness test.

During subsequent activities - pressure test, flushing and warm ELQA (under responsibility of the AT-MCS Pressure Test Coordinator), cool-down, commissioning, etc. - provision of the necessary support.

≥ Activities/ Status by sector

Data for General Advancement Plot is counted by number of interventions and grouped by activities as follows:

- IC preparation: Magnet alignment, IC pre-inspection, IC released for work,

- Electrical Interconnects & QA per halfcell: PAQ, US weld of spool pieces, brazing of main busbars,

- Cryo-Lines Welding & Testing: Welding of main busbar lines M1, M2, M3, weld K1 line, K2 line, K3 line, Cí line, X line. Vacuum tests of K lines, Cí line, X line.

- N-Line package: Insert N line, AIV 1, AIV 2, US welding of N line, weld of large sleeve for N line.

- Beam Pipes Welding & VAC tests. VAC sector test: Welding of V1, V2, E line and VAC tests V1, V2, E line. RF test magnet chain.

- Close W bellow and Jumper.

- VAC test for sector.

Status by sector

Sector 1-2 (completed)

Sector 2-3 (completed)

Sector 3-4 (completed)

Sector 4-5 (completed)

Sector 5-6 (completed)

Sector 6-7 (completed)

Sector 7-8 (completed)

Sector 8-1 (completed)

≥ Master Interconnection FlowDiagramm (Work Flow Chart)

also as download in pdf-format .

≥ Presentations/ Reports

MARIC 2006

- F. Bertinelli, presentation 24-May-06

- F. Bertinelli, presentation 21-Jun-06

- F. Bertinelli, presentation 02-Aug-06

- F. Bertinelli, presentation 13-Sep-06

- P. Fessia, presentation 25-Oct-06

- J.-Ph. Tock, presentation 08-Nov-06

- F. Seyvet, presentation 22-Nov-06

- J.-Ph. Tock, presentation 06-Dec-06

- F. Bertinelli, presentation 20-Dec-06

MARIC 2007

- J.-Ph. Tock, presentation 17-Jan-07

- F. Bertinelli, presentation 31-Jan-07

- J.-Ph. Tock, presentation 14-Feb-07

- P. Fessia, presentation 28-Feb-07

- J.-Ph. Tock, presentation 14-Mar-07

- C.Vollinger, presentation 14-Mar-07

- F. Bertinelli, presentation 28-Mar-07

- P. Fessia, presentation 25-Apr-07

- J.-Ph. Tock, presentation 09-May-07

- P. Fessia, presentation 23-May-07

- J-Ph. Tock, presentation 06-June-07

- F. Bertinelli, presentation 04-July-07

- P. Fessia, presentation 01-Aug-07

- J.-Ph. Tock, presentation 15-Aug-07

- P. Fessia, presentation 29-Aug-07

- J-Ph. Tock, presentation 12-Sep-07

- P. Fessia, presentation 26-Sep-07

- F. Bertinelli, presentation 26-Sep-07

- P. Fessia, presentation 10-Oct-07

- J-Ph. Tock, presentation 24-Oct-07

- P. Fessia, presentation 07-Nov-07

- J-Ph. Tock, presentation 21-Nov-07

- V. Parma presentation 21-Nov-07

- F. Bertinelli, presentation 05-Dec-07

TCC/ICC 2006

TCC/ICC 2007

- J-Ph. Tock, presentation 17-Aug-07

- F. Bertinelli, presentation 21-Sep-07

- P. Fessia, presentation 19-Oct-07

- J-Ph. Tock, presentation 19-Oct-07

- J-Ph. Tock, presentation 16-Nov-07

- J-Ph. Tock, presentation 30-Nov-07

- P. Fessia, presentation 14-Dec-07

Weekly Report on Interconnect works

2006

- Week 44 (October 30 - November 4, 2006).........................EDMS no. 792993

- Week 45 (November 6 - 11, 2006) .......................................EDMS no. 795112

- Week 46 (November 13-18, 2006)........................................EDMS no. 801078

- Week 47 (November 20-25, 2006)........................................EDMS no. 803276

- Week 48 (November 27 - December 2, 2006).....................EDMS no. 806283

- Week 49 (December 4 - 9, 2006)..........................................EDMS no. 808153

- Week 50 (December 11 -16, 2006).......................................EDMS no. 809773

2007

- Week 03 (January 15 - 20, 2007)..........................................EDMS no. 815113

- Week 04 (January 22 - 27, 2007)..........................................EDMS no. 816738

- Week 05 (January 29 - February 3, 2007)............................EDMS no. 818473

- Week 06 (February 5 - 10, 2007)..........................................EDMS no. 820233

- Week 07 (February 12 - 17, 2007)........................................EDMS no. 822035

- Week 08 (February 19 - 24, 2007)........................................EDMS no. 823184

- Week 09 (February 26 - March 3,2007)................................EDMS no. 826027

- Weeks 10-12 (March 5 - 24, 2007).......................................EDMS no. 831885

- Week 13 (March 26 - 31, 2007).............................................EDMS no. 833654

- Weeks 14-15 (April 2 - 14, 2007)..........................................EDMS no. 836627

- Week 16 (April 16 - 21, 2007)................................................EDMS no. 837942

- Week 18 (April 30 - May 5, 2007)..........................................EDMS no. 841677

- Weeks 19- 20 (May 7 - 19, 2007)..........................................EDMS no. 844850

- Week 21 (May 21 - 26, 2007)................................................EDMS no. 846684

- Week 22 (May 28 - June 2, 2007).........................................EDMS no. 847807

- Week 23 (June 04 - June 09, 2007)......................................EDMS no. 848915

- Week 24 (June 11 - June 16, 2007)......................................EDMS no. 850949

- Weeks 25 - 27 (June 18 - July 07, 2007)..............................EDMS no. 856890

- Week 28 (July 09 - July 14, 2007)..........................................EDMS no. 857550

- Weeks 29 - 32 (July 16 - August 11, 2007)...........................EDMS no. 861742

- Week 36 (September 03 - September 08, 2007)................EDMS no. 867107

- Week 39 (September 24 - September 30, 2007)................EDMS no. 871931

- Week 40 (October 01 - October 07, 2007)...........................EDMS no. 872748

- Week 41 (October 08 - October 14, 2007)...........................EDMS no. 874818

- Week 42 (October 15 - October 21, 2007)...........................EDMS no. 876055

- Week 43 (October 22 - October 28, 2007)...........................EDMS no. 878151

- Week 45 (November 05 - November 11, 2007)...................EDMS no. 882353

- Week 46 (November 12 - November 18, 2007)...................EDMS no. 883151

- Week 47 (November 19 - November 25, 2007)...................EDMS no. 884105

- Week 48 (November 26 - December 02, 2007)...................EDMS no. 884831

| Updated 19-December-07 by Olivier Denis |